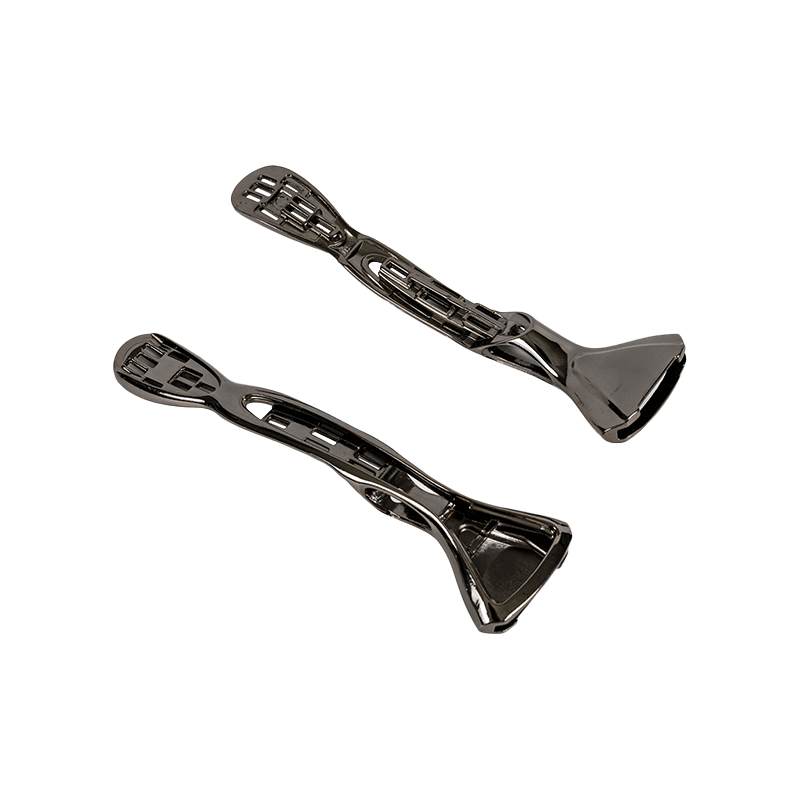

Ningbo Winsun Metal Products Co.,Ltd as China Professional OEM/ODM Shaver Handle Black Nickel Manufacturers and Custom Shaver Handle Bright Chrome Suppliers . Also is a company with responsibility for design,producing,distribution and specialized in making key safe boxes,electronic locks, padlock,electric towel rack,Ski rack and various of high quality zinc alloy accessories,e.g. zinc alloy lock accessories,shaver handles,bathroom accessories and other hardware products. We have passed the certification of ISO 9001 and PNC111.After over 10 years of production and development,now we equipped with a series of product equipment(die-casting machine,stamping machine,plastic injection machine) and professional technical teams which lead us to provide better services and products to customers.

founded in

company area

Total investment

Work experience