Industry Knowledge Extension

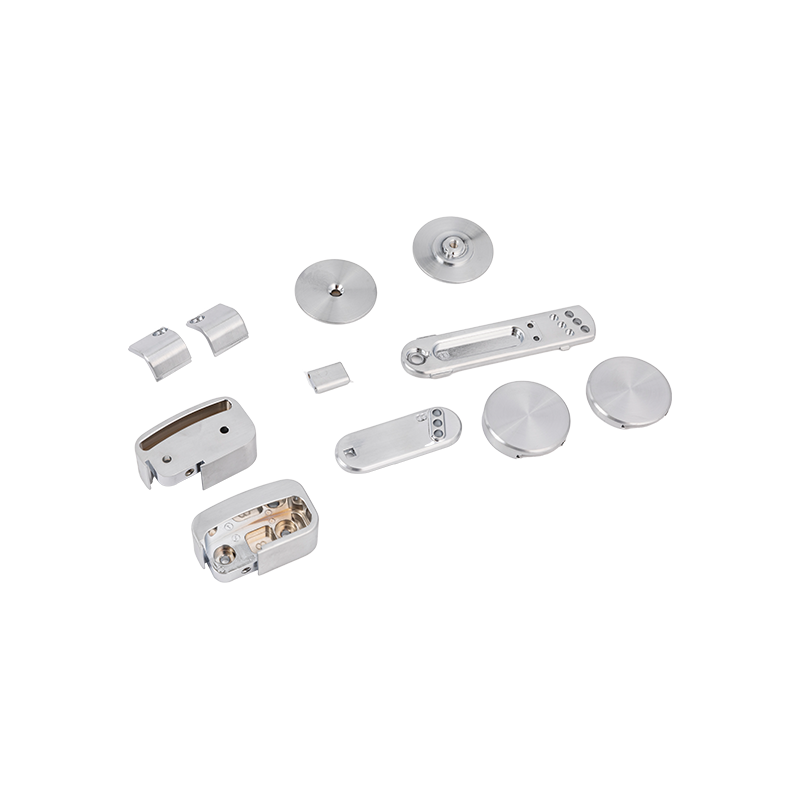

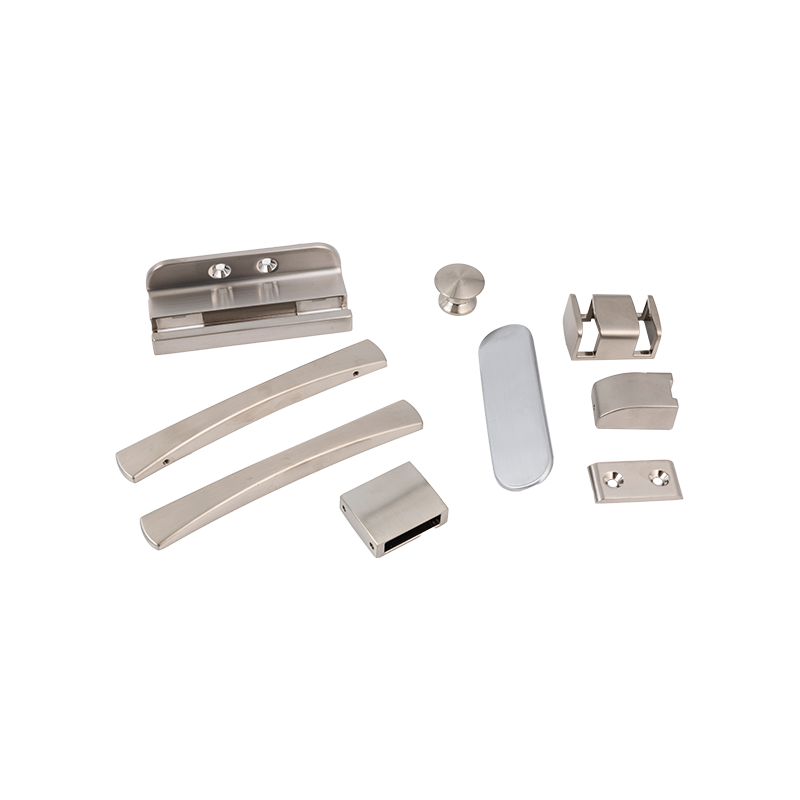

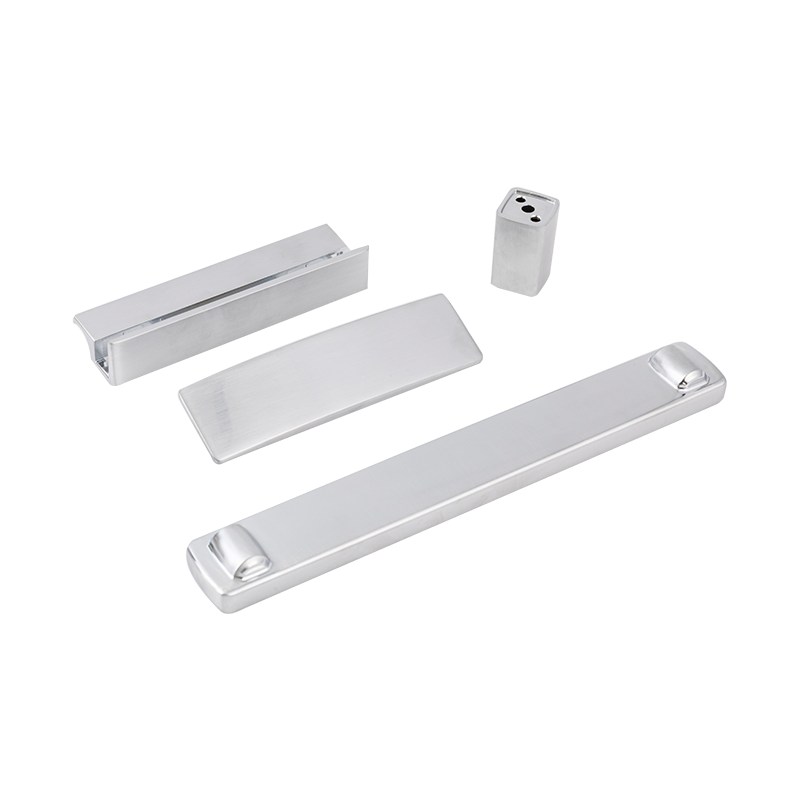

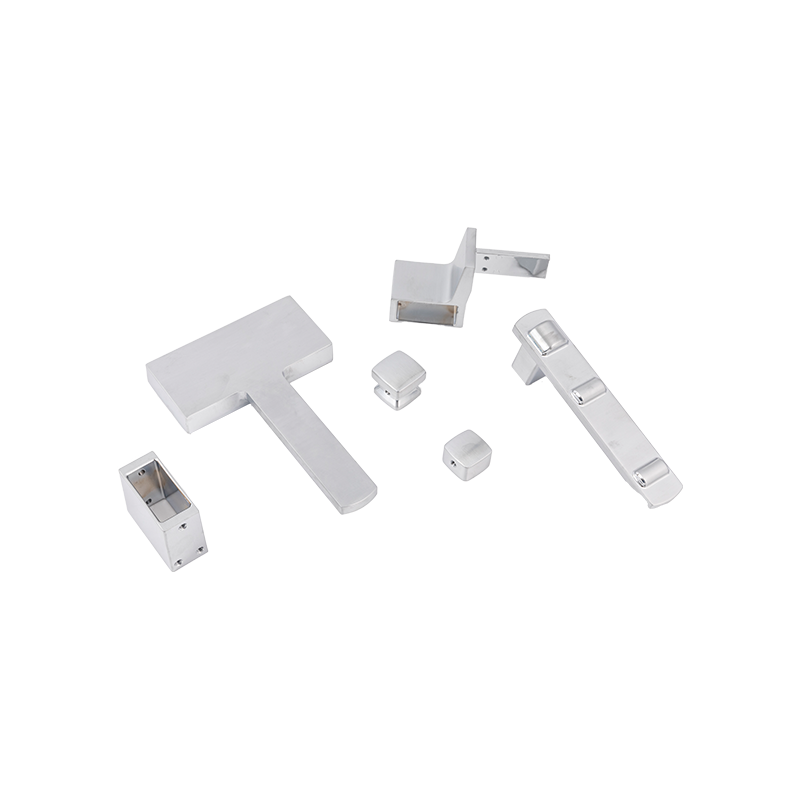

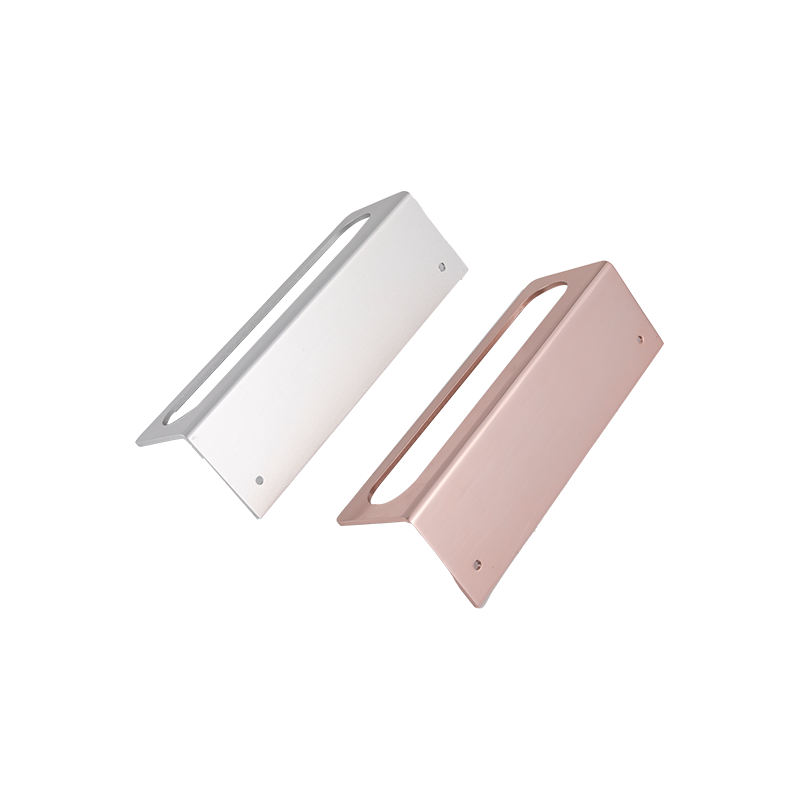

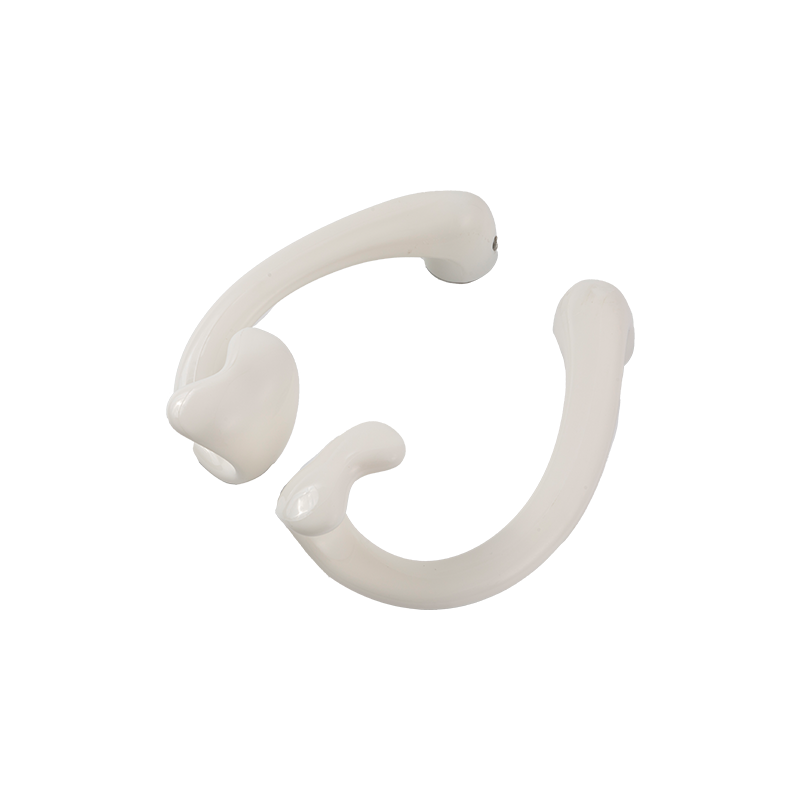

Window hardware fasteners can be made from a variety of materials, depending on their intended use, style, and durability requirements. Here are some common materials used in the construction of window hardware fasteners:

Metal: Metal is a popular choice for window hardware fasteners due to its strength and durability. Common metals used include stainless steel, brass, aluminum, zinc alloy, or iron. Metal fasteners offer robustness and are often resistant to corrosion and wear.

Plastic: Certain window hardware fasteners, particularly those designed for lightweight applications or non-load-bearing purposes, may be made from plastic materials. Plastic fasteners are lightweight, cost-effective, and resistant to rust or corrosion. They are commonly used in residential settings or for temporary solutions.

Composite Materials: Some window hardware fasteners may incorporate composite materials, such as reinforced plastics or fiberglass. These materials offer a combination of strength, durability, and resistance to weather elements. Composite fasteners are often used in areas where corrosion or weight is a concern.

Wood: Traditional or vintage-style window hardware fasteners may be made from wood. Wood fasteners provide a classic and rustic look, particularly suitable for wooden window frames. They are typically treated to resist moisture, insects, and warping.

Nylon or Polymer: In certain cases, window hardware fasteners may utilize nylon or polymer components. These materials offer lightweight properties, low friction, and resistance to chemicals. Nylon fasteners are often used for smoother operation and reduced noise when opening and closing windows.

The specific material used for window hardware fasteners may vary depending on factors such as aesthetics, functionality, budget, and intended application. It's important to select fasteners made from high-quality materials that can withstand the demands of regular use and environmental conditions.

Proper maintenance and care of window hardware fasteners can help ensure their longevity and optimal performance. Here are some general maintenance and care requirements for window hardware fasteners:

Regular Cleaning: Clean the window hardware fasteners periodically to remove dust, dirt, and debris that may accumulate over time. Use a mild detergent or soapy water solution and a soft cloth to clean the fasteners gently. Avoid abrasive cleaners or harsh chemicals that could damage the finish or components.

Lubrication: Apply a small amount of lubricant, such as silicone-based lubricant or light machine oil, to the moving parts of the window hardware fasteners. This helps ensure smooth operation and prevents friction or sticking. Be cautious not to over-lubricate, as excess lubricant can attract dirt and cause buildup.

Inspect for Damage: Regularly inspect the window hardware fasteners for any signs of damage, such as loose screws, bent components, or worn-out parts. If any damage is found, repair or replace the affected fasteners promptly to maintain functionality and security.

Tighten Loose Screws: Check the screws or bolts that secure the window hardware fasteners to the window frame. If any screws are loose, tighten them carefully to ensure a secure fit. Avoid over-tightening, as it can strip the threads or cause damage.

Protection from Harsh Weather: If the window hardware fasteners are exposed to extreme weather conditions, consider using protective measures. For example, in coastal areas or areas with high humidity, corrosion-resistant coatings or materials can help prevent rust or deterioration.

Avoid Excessive Force: Handle the window hardware fasteners with care and avoid applying excessive force when operating them. Rough handling or excessive force can lead to damage or misalignment of the fasteners. Operate them smoothly and gently to minimize wear and tear.

Keep Clear of Paint or Sealants: During painting or sealing projects, take care to keep the window hardware fasteners free from paint or sealant. These substances can interfere with the proper functioning of the fasteners or affect their appearance. If needed, protect the fasteners with masking tape or remove them temporarily during such projects.

Follow Manufacturer's Instructions: Always follow the manufacturer's instructions and guidelines for maintenance and care specific to your window hardware fasteners. They may provide specific recommendations for cleaning, lubrication, or other maintenance procedures.

By following these maintenance and care practices, you can ensure that your window hardware fasteners remain in good condition, operate smoothly, and contribute to the overall functionality and aesthetics of your windows.